Flash Trains

SysCAD recognises simple and complex arrangements of connected equipment that produces steam and consumes (condenses) steam. The solver then automatically solves for operating pressure based on the equipment and available duty at the condensers. This powerful feature in SysCAD is used in “flash trains” such as digestion, evaporation and crystaliser circuits.

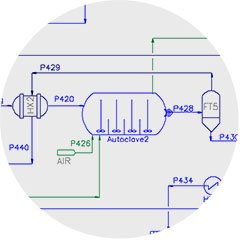

Reactors

Model the process chemistry in reactors and various equipment. SysCAD includes a flexible reaction block model where there are numerous options to define and control chemical reactions, including heats of reactions, so that your process chemistry can be modeled in a number of ways. A range of other specific reaction types such as solubility and flashing can be configured to be used in the process plant model.

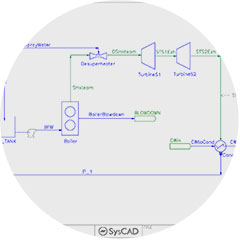

Steam Distribution

Design and analyse detailed steam production and distribution systems. Determine and minimise the cost of energy to provide steam for the process. SysCAD includes capabilities for steam processing equipment and detailed H2O properties for accurate modelling of energy balance and performance.

Plant Control

Use flexible controller blocks to implement simple or sophisticated control logic. In a dynamic simulation project emulate the control system and operating rules. This powerful feature is used for custom calculations for reporting and for manipulating unit models to accurately simulate your plant specific equipment.

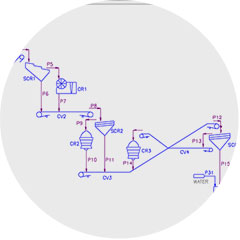

Size Distribution

Optionally track particle size distributions of single or multiple solids through crushing, screening and hydrocyclones. Analyse agglomeration and growth of particles in detailed precipitation tank models. SysCAD will maintain particle balances across the process and recycles.

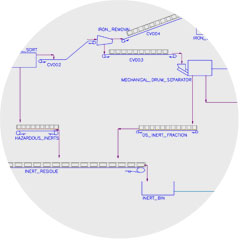

Material Handling

In dynamic simulation applications you can model detailed conveying systems, stockpiles, tanks, etc and interactions with discrete events such as trucking schedules, failures and scheduled maintenance. Evaluate surge and availability, or the impacts of different operating stratagies.

Other

A wide range of different process circuits can be modeled using SysCAD. Many examples of processes, circuits and equipment that has been modeled in SysCAD is listed here. Using the building blocks in SysCAD almost any equipment or process can be modeled, or contact us so that we can expand the capabilities available in SysCAD.

Process / Circuit

- Autoclave

- Carbon in Pulp (CIP)

- Cogeneration / Power Plant

- Combustion

- Condensation

- Counter Current Decantation (CCD)

- Crushing and Screening

- Crystallisation

- Desalination/Reverse Osmosis

- Digestion

- Evaporation / Flashing / Drying

- Flash Train

- Foundry

- Ion Exchange

- Kiln

- Leaching including Heap Leaching

- Material Handling (stockpiles, conveying)

- Milling

- Precipitation / Dissolution

- Reforming

- Resin in Pulp (RIP) (Adsorption and Elution)

- Smelting / Furnaces

- Solvent Extraction / Scrubbing / Stripping

- Water Treatment

Equipment

- Blenders

- Boilers

- Centrifuges

- Conveyors

- Cooling Towers

- Desuperheaters

- Electrowinning Cells

- Falling Film Evaporators

- Filters

- Flotation Cells

- Heat Exchangers

- Heaters / Coolers

- Hydrocyclones

- Mixers

- Multistage Columns

- Pumps, Valves, Compressors

- Reactors

- Separators (General, Spirals, Magnetic)

- Steam Turbines

- Stockpiles

- Tailings Dams

- Tanks

- Thickeners / Washers