Sugar is one of the most important agricultural commodities in the world with a global production of around 180 million tonnes per year[1]. To supply the staggering demand for sugar and ethanol, over 2 billion tonnes of sugar crops – sugar cane and sugar beets – are harvested annually[2]. In fact, sugar cane is the world’s most produced agricultural crop, representing 88% of sugar crops and 20% of all primary crops!

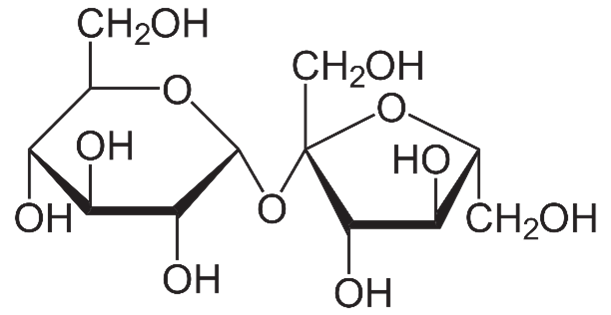

While there are other commercial sugars (e.g. high-fructose corn syrup), the sweetener market is dominated by white sugar – refined crystals of sucrose, essentially a bonded glucose-fructose molecule (C12H22O11).

Sugar processing from crop to crystal generally occurs in two separate processing plants. Sugar mills process the harvested crops into raw sugar which is then sent to sugar refineries where the raw sugar is remelted, purified and crystalised into specific products. Consumer sugar products include granulated sugar, brown sugar, powdered sugar, demerara, turbinado and muscovado.

Sugar processing from crop to crystal generally occurs in two separate processing plants. Sugar mills process the harvested crops into raw sugar which is then sent to sugar refineries where the raw sugar is remelted, purified and crystalised into specific products. Consumer sugar products include granulated sugar, brown sugar, powdered sugar, demerara, turbinado and muscovado.

While the sugar production process has its roots in agriculture, it is an industrial process in terms of throughput, equipment size, energy use and raw materials consumption. Consolidation of the industry in response to high demand has resulted in large sugar refineries which can produce in the order of 1 million tonnes per year – comparable with large chemical and mineral refineries.

As in any industry, there is constant pressure to reduce manufacturing costs, energy consumption, and carbon footprint. Process simulation in SysCAD with the Sugar Add-On allows you to find the sweet spot for process design, operation and optimisation.

Raw Sugar Production

Raw Sugar Production

Sugar cane contains ~14% sucrose by weight, existing in solution within the plant cells. When sugar cane is harvested, the leaves are removed and the stalks are chopped into lengths for transport. At the sugar mill the stalks are shredded then crushed to rupture the plant cells and extract the juice.

The juice is heated, mixed with lime, and clarified before going to a multistage evaporation process to remove water, typically in rising or falling film evaporators. Here the juice is concentrated to a syrup around 70°Bx (degrees Brix – the mass percentage of solute, typically used for dissolved sugar). While the solutes are mostly sucrose, there are other sugars and impurities present.

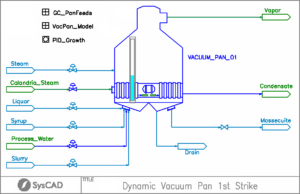

The syrup is then fed into vacuum pans along with sucrose seed crystals (footing). The vacuum pans have a built-in heat exchanger (calandria) and typically run as a batch process (strike). Using low pressure steam in the calandria, the pan is heated and the mixture of syrup and crystal (massecuite) is boiled under vacuum at about 65°C. The pan is connected to a condenser which condenses the steam coming from the pan, driving the vacuum inside the vessel. As the water boils off, the syrup becomes supersaturated in sucrose which crystallises onto the footing. During the strike, more syrup is fed into the vacuum pan to maintain a consistent supersaturation for controlled precipitation. As sucrose precipitates and water is evaporated, the concentration of impurities increases. The strike ends when purity reaches a minimum value, precipitation rate is too slow, or the pan volume is full.

The resulting sugar crystals are virtually pure sucrose – even though they are precipitated from a solution high in impurities, their concentration is never enough for them to precipitate.

The resulting sugar crystals are virtually pure sucrose – even though they are precipitated from a solution high in impurities, their concentration is never enough for them to precipitate.

The pan contents are then dropped into a batch centrifuge which spins off the remaining syrup with impurities (molasses), retaining the sugar crystals. While the centrifuge is running, wash water is used to remove residual molasses. The sugar crystals are ploughed out of the centrifuge and hot water is used to wash any remaining sugar from the centrifuge basket.

The molasses still contains recoverable sugar and most sugar mills have multiple stages of vacuum pans (A, B and C pans) to reprocess the molasses with increasing impurities concentration. This is often followed by crystallisers, a type of continuous precipitator used to extract the last recoverable sugar from the molasses.

Most of the resulting pure sugar crystals are sent to a dryer and leave as product raw sugar, though some fine particles are retained as footing for the next strike.

Beet sugar production begins with slicing washed beets and using a diffusion process to extract the sugar. The juice then goes to clarification and from there the process is essentially the same as for sugar cane. The final product of both beet and cane sugar is nearly identical despite being derived from two different crops.

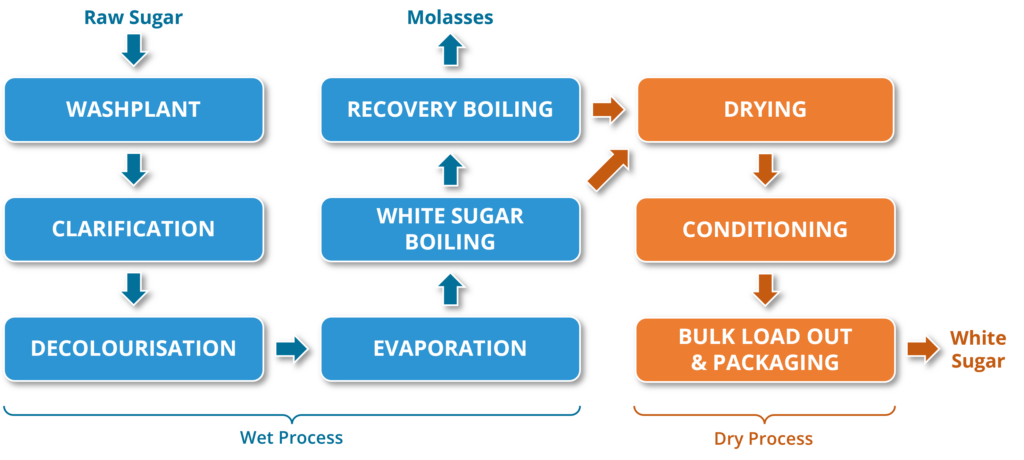

Refined Sugar Production

White sugar is processed from raw sugar in a sugar refinery. Here the raw sugar is dissolved (melted) into sugar liquor with hot water, then clarified and filtered to remove impurities and colour bodies. Similar to the mills, the liquor is sent to vacuum pans where it is boiled under vacuum until it reaches supersaturation. The liquor is seeded with very fine crystals (~10 µm) which act as initial nucleation sites, promoting uniform crystal growth. The pure sugar crystals grow to product size by the end of the strike, where the massecuite is then centrifuged to remove the molasses. The recovered crystals are dried and shipped as product refined sugar and the molasses goes through further strikes to recover more sugar before it finally becomes product molasses.

White sugar is processed from raw sugar in a sugar refinery. Here the raw sugar is dissolved (melted) into sugar liquor with hot water, then clarified and filtered to remove impurities and colour bodies. Similar to the mills, the liquor is sent to vacuum pans where it is boiled under vacuum until it reaches supersaturation. The liquor is seeded with very fine crystals (~10 µm) which act as initial nucleation sites, promoting uniform crystal growth. The pure sugar crystals grow to product size by the end of the strike, where the massecuite is then centrifuged to remove the molasses. The recovered crystals are dried and shipped as product refined sugar and the molasses goes through further strikes to recover more sugar before it finally becomes product molasses.

Process Modelling for the Sugar Industry

A high-quality simulation of your sugar mill or refinery is essential for process optimisation, energy efficiency, and product quality control. A model built on solid principles can be used to better understand your process for operational management, to identify operational weaknesses and bottlenecks, and to evaluate and prioritise process improvements.

The SysCAD modelling platform, established in minerals processing and trusted by owner-operators and consultants in various fields, represents a comprehensive solution for the sugar industry. SysCAD is specifically designed for aqueous chemistry and solids handling and features both steady-state and dynamic solver modes for accurate modelling of batch processes. The robust and flexible platform allows for accurate representation of control schemes and offers seamless integration with Excel and other software for data input and reporting.

SysCAD provides the necessary tools for project justification, cost modelling, annual planning, performance evaluation, surge and availability studies, control system testing, energy and water consumption management, and employee training support. A comprehensive model acts as a central repository for all your process information.

SysCAD offers a specialised Sugar Add-On including several sugar species models to calculate the thermophysical properties of pure and technical sucrose solutions over the typical range of temperatures and concentrations found in industry. These properties have been adapted from the Sugar Technologists Manual[3], with boiling point elevation using a more recent formulation[4].

The Sugar Add-On unit models are available in both Steady-State and Dynamic solver modes:

- Cane Shredder

- Crusher

- Juice Screen

- Mud Filter

- Vacuum Pan

- Crystalliser

- Fugal (Centrifuge)

- Dryer

SysCAD is also shipped with a range of Sugar Example Projects that demonstrate the use of these unit operations and the sugar species properties models. Developed and supported by a global team, SysCAD has been applied in many mills and refineries to assist with simulating their process[5].

As presented at the Sugar Industry Technologists (SIT) 2024 Annual Technical Meeting, SysCAD has been used to model a Sugar Vacuum Pan that dynamically predicts crystal growth using machine learning and neural networks[6]. Since the properties of high-concentration sucrose solutions are non-ideal, and the boiling pan process involves several physical and chemical phenomena taking place simultaneously, the use of machine learning within SysCAD has helped to optimise this complex area of the process.

Resources

- Online Documentation: Sugar Species Model, Sugar Unit Models

- SysCAD is distributed with a range of Example Sugar Projects, including milling, clarification, falling film evaporation and vacuum panning.

- Please contact us to arrange a presentation or Trial Download.

References

- USDA Foreign Agricultural Service (2024) “Production – Sugar” (Accessed 26 Mar 2024)

- FAO (2023) “World Food and Agriculture – Statistical Yearbook 2023”

- Z. Bubník et al. (1995) “Sugar Technologists Manual” ed. 8, Bartens, Berlin

- M. Saska (2002) “Boiling Point Elevation of Technical Sugarcane Solutions and its use in Automatic Pan Boiling”, International Sugar Journal, vol. 104, no. 1247, pp. 500-507

- A. Mann, O. Thaval, R. Broadfoot, J. McFeaters (2015) “Improving Factory Performance using an Integrated Sugar Factory Model” 37th Annual Conference of the Australian Society of Sugar Cane Technologists, pp. 305-315

- E. Smyth, T. Marin, E. McFeaters (2024) “SysCAD Neural Network Models for LSD Dynamic Sugar Crystal Growth Prediction”, SIT Annual Technical Meeting 2024