Many industrial and mineral processes are dependent on highly complex chemical interactions. These reactions and thermochemical processes are often simplified in traditional process simulation. Process efficiencies, however, are often found “close to the edge”. As such, a thorough understanding of process chemistry is key to better design, efficient operation, and real-world optimisation.

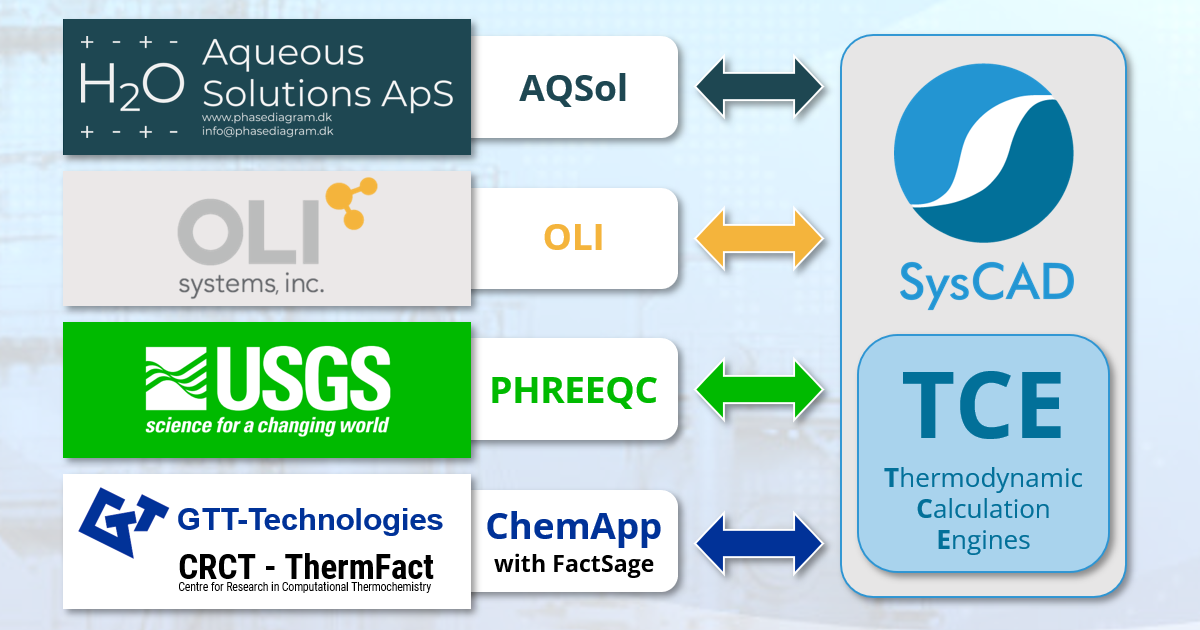

With the introduction of Thermodynamic Calculation Engines (TCEs), SysCAD has significantly expanded its modelling capabilities for pyrometallurgy, hydrometallurgy, crystallisation and water treatment applications, by allowing incorporation of third-party thermochemical equilibrium solvers directly into the process flowsheet.

Thermodynamic Calculation Engines

SysCAD seamlessly integrates a growing number of TCEs including AQSol, OLI, PHREEQC and ChemApp via a familiar universal interface. The SysCAD flowsheet solver maintains the global mass and energy balances as well as the mapping between SysCAD and TCE chemical species definitions, while the TCEs provide targeted application of high-fidelity phase equilibrium and solution property calculations to enhance your process simulation.

AQSol

AQSol

- Thermodynamic phase equilibrium for multi-component systems

- Concentrated electrolyte solution chemistry for crystallisation and water treatment

- Tailor-made custom databases for specific applications

OLI

- Complex water chemistry for mixed solvent electrolytes using industry leading data

- Applications in concentrated solutions for water treatment and hydrometallurgy

- Includes Mixed Solvent Electrolyte model for very high concentration solutions

PHREEQC

- Aqueous geochemical calculations, activity coefficient models and surface complexation

- Applications in water treatment, tailings management and mineral salts

- Databases are freely modifiable and open source

ChemApp

- Complex multi-phase equilibrium, thermochemical calculations with energy balance

- High temperature pyrometallurgical applications

- Can incorporate thermodynamic databases generated from the FactSage family of products

SysCAD also includes an inbuilt Gibbs Free Energy Minimisation unit model, aimed primarily at ideal solutions such as combustion and pyrometallurgy.

Flexible Solutions for Design and Operation

A suite of TCE-enabled unit operations is included with the TCE add-ons, useable in both steady-state and dynamic models. These reactors and calculators interact seamlessly with other SysCAD unit models and streams, including other thermodynamic engines within the same flowsheet.

Unlike traditional reaction-based methods for modelling process unit operations, TCE-enabled units do not require specification of reactions or extents, but rather determine the reactions required to achieve the minimum free energy state of the system. By optionally suppressing the formation of species with slow kinetics or constraining the participation of species, TCE reactions can be tuned for real-world operation at non-equilibrium conditions.

Not every part of a flowsheet requires high-accuracy TCE calculations. As a tool of choice for practical engineers, SysCAD allows the use of detailed calculations as needed, with faster generic calculations used elsewhere (such as solubility functions, controlled extent reactions and vapour-liquor equilibrium). This hybrid approach, combined with the fast multithreaded solver within SysCAD, allows for rapid computation of complex flowsheets of varying size. Further flexibility is available through use of the TCE calculations applied as inline reactions or used to inform setpoints for SysCAD reaction blocks.

Not every part of a flowsheet requires high-accuracy TCE calculations. As a tool of choice for practical engineers, SysCAD allows the use of detailed calculations as needed, with faster generic calculations used elsewhere (such as solubility functions, controlled extent reactions and vapour-liquor equilibrium). This hybrid approach, combined with the fast multithreaded solver within SysCAD, allows for rapid computation of complex flowsheets of varying size. Further flexibility is available through use of the TCE calculations applied as inline reactions or used to inform setpoints for SysCAD reaction blocks.

For process design engineers, these models are very useful at all stages of design, from concept through to detailed engineering and commissioning. A robust thermodynamic equilibrium model can identify potential design issues as well as opportunities for improved efficiency, cost reduction and optimal environmental performance.

For operating plants, thermodynamic equilibrium predictions provide a means to evaluate process changes, identify bottlenecks and diagnose causes of operational issues. Comparison of TCE simulation results with measured plant data can identify gaps in process knowledge where targeted test work is required, or identify faulty equipment or sensors.

Real-World Examples

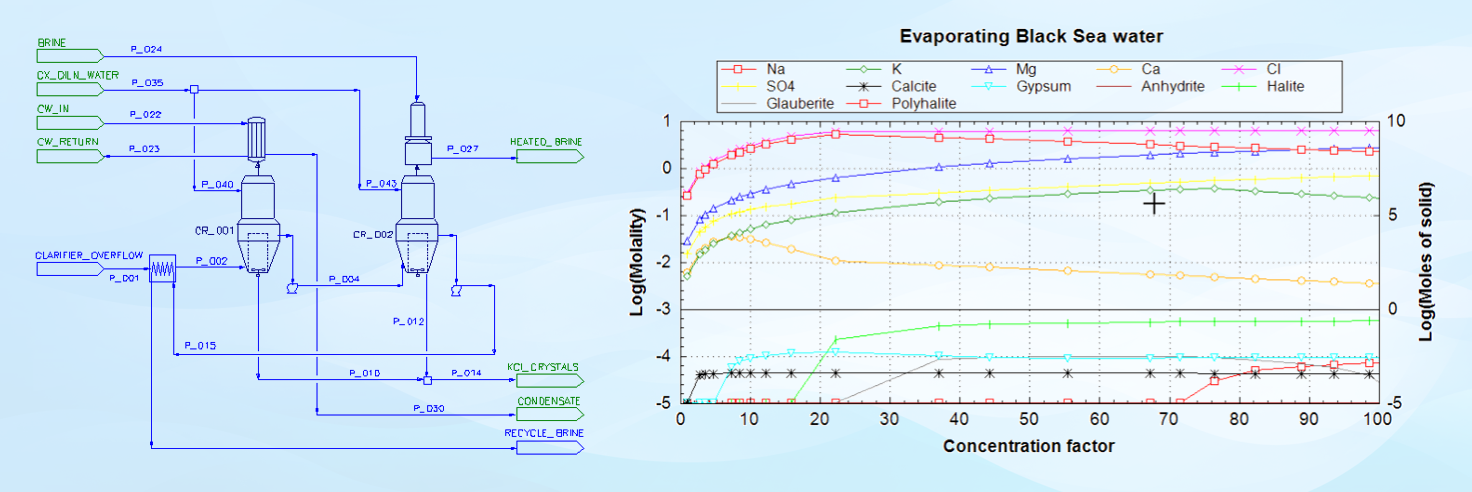

Pond and Evaporator Operation

TCEs in SysCAD can provide significant value in the crystallisation of mineral salts from multicomponent solutions and brines. In these hydrometallurgical and water treatment processes, the water concentration in crystallisers, ponds and evaporators is modified to achieve purity specifications, exploiting the difference in product and impurity solubilities. When the water balance is suboptimal, either too much of the targeted species remains in solution, derating process efficiency, or too many undesired products are coprecipitated, directly affecting product value. A detailed thermodynamic model is critical for accurately calculating solubility boundaries which can be used as controller setpoints to optimise water balance targets. Together with plant measurements, this can maximise plant capacity and minimise energy costs while ensuring product quality.

TCEs in SysCAD can provide significant value in the crystallisation of mineral salts from multicomponent solutions and brines. In these hydrometallurgical and water treatment processes, the water concentration in crystallisers, ponds and evaporators is modified to achieve purity specifications, exploiting the difference in product and impurity solubilities. When the water balance is suboptimal, either too much of the targeted species remains in solution, derating process efficiency, or too many undesired products are coprecipitated, directly affecting product value. A detailed thermodynamic model is critical for accurately calculating solubility boundaries which can be used as controller setpoints to optimise water balance targets. Together with plant measurements, this can maximise plant capacity and minimise energy costs while ensuring product quality.

Smelter and Furnace Design

TCE calculations provide invaluable insight for process design where conditions fall outside the normal range, such as testing new blends of feed reagents or changing process temperatures. A SysCAD model using TCE can predict process performance, aiding design and optimising the required test work while mitigating risks associated with large-scale piloting. For example, in pyrometallurgical processes, a thermodynamic model of a smelting furnace can accurately predict the impact of minor elements or oxides on important slag properties (liquidus temperature, phase deportment, etc.). This can be used to define safe operating zones where product recovery is optimised, and refractory brick integrity and process safety is ensured.

TCE calculations provide invaluable insight for process design where conditions fall outside the normal range, such as testing new blends of feed reagents or changing process temperatures. A SysCAD model using TCE can predict process performance, aiding design and optimising the required test work while mitigating risks associated with large-scale piloting. For example, in pyrometallurgical processes, a thermodynamic model of a smelting furnace can accurately predict the impact of minor elements or oxides on important slag properties (liquidus temperature, phase deportment, etc.). This can be used to define safe operating zones where product recovery is optimised, and refractory brick integrity and process safety is ensured.

Getting Started

For more information on Thermodynamic Calculation Engines within SysCAD, please visit our online help documentation or contact us at info@syscad.net. SysCAD is shipped with a range of TCE demo version and full version example projects.

Integration of TCEs in SysCAD requires the correct license options from SysCAD as well as from TCE suppliers:

- AQSol – Aqueous Solutions ApS

- OLI Engine – OLI Systems, Inc.

- PHREEQC – U.S. Geological Survey

- ChemApp – GTT-Technologies

- Allows use of databases created using the FactSage family of products – GTT-Technologies & CRCT ThermFact

References

- “Evaporating Black Sea Water” graph from: D.L. Parkhurst, C.A.J. Appelo (2013) “Description of input and examples for PHREEQC version 3—A computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations”, U.S. Geological Survey Techniques and Methods, Book 6, Chap. A43, 497p